It is an oldie and had some hurts so I spent a few hours working on it. It has been cleaned and lubricated. I restored the clicker function [edited], as the spring was completely broken off and had already been removed. Thanks to prior Reel Talk posts by several of the experts like John Elder, Warren Platt and Steve Vernon, I was able to figure out the clicker spring fix without having to ask. However, the old pics in those posts are being held for ransom by Photobucket so I decided to post my own here for future reference.

I cleaned up the foot, too. It was crudely altered and defaced underneath so I didn't feel obliged to leave it that way. I need to find correct foot screws. The ones that came with the reel fit in the threads but the correct screw needs to be the countersunk variety so it sits flat on the foot. Also, the ivory handle has shrunk and is starting to fracture. I decided to leave the grasp pivot screw full length. I will find a suitable washer so that it makes up for the shrinkage of the grasp and lines it up at the top screw head. I have recently seen a technique using superglue and baking soda to repair/reinforce bone etc so may try that after I have practiced a bit on something else first.

Anyway here is a video of the finished reel followed by before, internal and after pics:

Before:

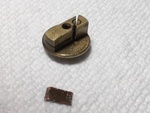

Clicker spring broken off in slider switch. What you see is an optical illusion. The switch is a block of brass with a channel through which the spring lies. The round thing is a moat. It appears that a tube-like punch tool was used to strike the spring and hold it in place at two points in the moat, sort of like peening the spring in place. As discussed in the 2008 post on this subject, a tiny screwdriver and hammer are used to tap out the old spring from the tight slot. The second photo shows the old spring remnant removed. I copied the general spring shape from a Meek & Milam sitting on my shelf and that worked fine for me. Note the perpendicular slot that acts as a spring to hold the switch with just the right amount of tension against the faceplate.

As the earlier post suggested, I used the metal from a spring clip, cutting the strip I needed with tin snips. I also tried the spring from an old fly reel but that was too thick and brittle. My clip is held in place using a shim of the same material. I didn't need to cut the width of the metal strip too precisely as there is plenty of clearance.

The defaced foot before cleanup. I was wondering why someone went to the trouble of scouring the underside. As I was cleaning it up, the mystery was solved. Crudely scratched initials "S W" appeared underneath. I decided to remove them. As stated above, I reshaped the foot to reduce the abruptness of the alteration.

AFTER: