What Was the 1st Reel to Use Precision Ball Bearings?

OK

Ron, I will work some of this into an article but I can't promise to get to the bottom of it all! But sometimes its not the answers that matter but asking the right questions in the first place...the answers Copernicus furnished were wrong, but he put the world on the right track by asking the right question.

Anyway, I did some digging around and came up with some interesting items about ball bearings and fishing reels. The first reference I could find to them in national literature was Alfred C. Harmsworth's "An Englishman's Experience of Florida Fishing" (1895) in which he noted his reel of choice for Tarpon fishing was as follows: "The reel is a Vom Hofe 'silver King.' It costs, I think, 6 [pounds] but is worth it. It runs on ball bearings and with marvelous freedom. It is comparatively light and has stood the strain of catching a half dozen sharks measuring from 7 feet to 9 feet in length." Later he noted "I have described for you the stiff 7 foot [Conroy] rod and the big reel that runs on ball bearings and carries 600 feet of fine salmon line." So he found the Vom Hofe reel and its ball bearings sufficiently important to note in his excellent study of early tarpon fishing. So we know before the turn of the century ball bearing reels were noted, at least by one writer, for their durability.

The first advertisement I could come up with (I'm sure there are earlier ones but I haven't found one) that SPECFICALLY noted bearings was a Meisselbach Takapart ad from 1919 (see below). It noted "pivots turn in the shaft with Ball End Bearings. Ball bearings in head and rear plates."

Another interesting reference to ball bearings and reels comes from a fascinating article by W.J. Schaldach, "A Brief Chapter on Reels" (1922), where he gives a brief history of reels and an analysis of the current state of reelmaking. He noted: "Some reels are equipped with jeweled bearings while others with phosphor bronze and steel bearings. The former kind are usually the most costly, although some of the most expensive reels have plain bearings, and will wear a life time. The reason that the bearings of most reels wear away is because of insufficient lubrication." So clearly ball bearings were well enough known by 1922 to warrant a write up, even if they weren't the precision chrome steel ball bearings that would be created just a couple of years later.

This leads us to the 1940s, when the ball bearing maker was noting that fishing reels were utilizing precision ball bearings. I was able to uncover what I believe is one of the reels that was utilizing these bearing assemblies. It was from an Abercrombie & Fitch ad (1947) touting a Bushkill Fly Reel--it mentioned in the ad "lifetime ball bearings." This ad is reproduced below. Does anyone know who made the Bushkill for A&F?

Finally, precision ball bearings were still important enough to make news in the 1990s. The New York Times published an article entitled "A Big Reel for those Big Fish" (19 September 1992) about the new ABU Pro Max 3800. It noted "The Pro Max reel is made with eight ball bearings, which make the spool run smoothly and freely, and add support to the reel, Mr. [Jerry] Gomber said. Most manufacturers use two or three ball bearings." Gomber was the business manager of ABU Garcia at the time.

Anyway, I did some digging around and came up with some interesting items about ball bearings and fishing reels. The first reference I could find to them in national literature was Alfred C. Harmsworth's "An Englishman's Experience of Florida Fishing" (1895) in which he noted his reel of choice for Tarpon fishing was as follows: "The reel is a Vom Hofe 'silver King.' It costs, I think, 6 [pounds] but is worth it. It runs on ball bearings and with marvelous freedom. It is comparatively light and has stood the strain of catching a half dozen sharks measuring from 7 feet to 9 feet in length." Later he noted "I have described for you the stiff 7 foot [Conroy] rod and the big reel that runs on ball bearings and carries 600 feet of fine salmon line." So he found the Vom Hofe reel and its ball bearings sufficiently important to note in his excellent study of early tarpon fishing. So we know before the turn of the century ball bearing reels were noted, at least by one writer, for their durability.

The first advertisement I could come up with (I'm sure there are earlier ones but I haven't found one) that SPECFICALLY noted bearings was a Meisselbach Takapart ad from 1919 (see below). It noted "pivots turn in the shaft with Ball End Bearings. Ball bearings in head and rear plates."

Another interesting reference to ball bearings and reels comes from a fascinating article by W.J. Schaldach, "A Brief Chapter on Reels" (1922), where he gives a brief history of reels and an analysis of the current state of reelmaking. He noted: "Some reels are equipped with jeweled bearings while others with phosphor bronze and steel bearings. The former kind are usually the most costly, although some of the most expensive reels have plain bearings, and will wear a life time. The reason that the bearings of most reels wear away is because of insufficient lubrication." So clearly ball bearings were well enough known by 1922 to warrant a write up, even if they weren't the precision chrome steel ball bearings that would be created just a couple of years later.

This leads us to the 1940s, when the ball bearing maker was noting that fishing reels were utilizing precision ball bearings. I was able to uncover what I believe is one of the reels that was utilizing these bearing assemblies. It was from an Abercrombie & Fitch ad (1947) touting a Bushkill Fly Reel--it mentioned in the ad "lifetime ball bearings." This ad is reproduced below. Does anyone know who made the Bushkill for A&F?

Finally, precision ball bearings were still important enough to make news in the 1990s. The New York Times published an article entitled "A Big Reel for those Big Fish" (19 September 1992) about the new ABU Pro Max 3800. It noted "The Pro Max reel is made with eight ball bearings, which make the spool run smoothly and freely, and add support to the reel, Mr. [Jerry] Gomber said. Most manufacturers use two or three ball bearings." Gomber was the business manager of ABU Garcia at the time.

Anyone know why the images didn't come up?

Does anyone know why the images didn't come up?

-

Reel Geezer

- Ultra Board Poster

- Posts: 2314

- Joined: Sat Sep 13, 2003 11:06 pm

- Location: On the Snake River or Lake Lowell

- Contact:

In 1914, Perry Frazer differentiated between types of reel bearings: "Garnets are fitted in these bearings if desired, insuring longer wear than is possible with the customary steel bearings." He wasn't referring to ball bearings, and it doesn't sound to me that Schaldach was, either.

I'm still not sure what we're talking about here. Stefan pointed out that the Hardy Perfect employed ball bearings in the 1890s. The patent drawings I posted above showed, from left to right, (1) a roller bearing in a single-action reel patented by Graham in 1888, (2) a Meisselbach 1897 ball bearing, (3) Sutton's 1902 ball bearing, used in the America reels, and (4) Kopp's 1921 ball bearing, used in Winchester reels. Production reels employed ball bearings earlier than 1924.

So what are we asking? When was a reel first equipped with a Pierce-process-made bearing? When was a reel first equipped with a ball bearing made to some specified level of precision? Some particular alloy? Chrome plating? It would seem to me that reels with ball bearings have been, in general, more expensive than those without. And among reels with ball bearings, the more expensive ones might use ball bearings made with better precision than those used in cheaper ball-bearing-equipped reels. So I'm guessing that at any given time, reels were equipped with bearings of varying quality/precision, not much of a surprise. I still don't understand the question.

I'm still not sure what we're talking about here. Stefan pointed out that the Hardy Perfect employed ball bearings in the 1890s. The patent drawings I posted above showed, from left to right, (1) a roller bearing in a single-action reel patented by Graham in 1888, (2) a Meisselbach 1897 ball bearing, (3) Sutton's 1902 ball bearing, used in the America reels, and (4) Kopp's 1921 ball bearing, used in Winchester reels. Production reels employed ball bearings earlier than 1924.

So what are we asking? When was a reel first equipped with a Pierce-process-made bearing? When was a reel first equipped with a ball bearing made to some specified level of precision? Some particular alloy? Chrome plating? It would seem to me that reels with ball bearings have been, in general, more expensive than those without. And among reels with ball bearings, the more expensive ones might use ball bearings made with better precision than those used in cheaper ball-bearing-equipped reels. So I'm guessing that at any given time, reels were equipped with bearings of varying quality/precision, not much of a surprise. I still don't understand the question.

Precision Ball Bearings

Steve,

There is a very real distinction between a ball bearing and a precision ball bearing. One distinction, as defined by Fuji Seisakusho's web site (they make ball bearings), is that precision ball bearings are required to have a tolerance over a micron (1/1000mm). Commercial ball bearings (also called unground ball bearings) have a tolerance of 1/100mm to 1/10mm. This is of course current terminology. As I mentioned previously, it was not until the WWII era where precision ball bearings became possible, in particular precision micro ball bearings. The distinction is made well in the following passage from a bearing manufacturer site:

"Commercial unground ball bearings are available as radial, thrust, or combination types. Basically, these ball bearings are made of a machined or stamped inner race, a full complement of hardened steel balls, and an outer race of one, two, or more machined or stamped parts...Misalignment has little effect on commercial unground ball bearing assemblies because of their greater internal clearances. Excessive misalignment destroys any bearing, but far less production accuracy is required with unground ball bearings. As a result, the entire assembly can be much simpler in construction than a precision bearing. The major advantage of unground ball bearings over the higher precision ball bearings discussed earlier is price. Unground ball bearings are far less expensive than the higher precision types. On the other hand, life of unground ball bearings is less than precision bearings...Unground ball bearings also operate at higher noise than precision bearings."

Now, as for fishing reels, my original question was precise: What was the first reel to use precision ball bearings? I later refined it to ask when fishing reels first utilized micro precision ball bearings. Basically, Steve, what this is all getting at is when the fishing reel industry first required such hyper technical precision when constructing their models. If you look at the specs of many modern reels such as the Swift Center-Pin Trotting Reel, GALAXY 600 BR, Daiwa Gyro Spin, Epix ER40 and many other reels, they SPECIFICALLY indicate precision ball bearings, meaning that these bearings have enormously high tolerances even when compared to standard bearings. The benefits of a precision ball bearing are many, including longer life, more precise mechanics, and smoother and more silent operation. The benefits of commercial ball bearings are price and degree of clearance. It should not be a surprise that many of the high-end reels advertise precision ball bearings. What I am trying to ascertain, for my own personal edification if nothing else, is when this shift happened and who was the first to do it.

You ended your series of questions with the following comment: "So I'm guessing that at any given time, reels were equipped with bearings of varying quality/precision, not much of a surprise." No, maybe not a surprise, but the creation of greater precision in fishing reel design is still perhaps one of the most important developments in the last 50 years of fishing reel design history. Precision ball bearings appear to have played an important role in this. Is that not worthwhile discussing?

The discussion here of when reels first utilized ball bearings is a logical outgrowth of trying to figure out when they switched from the equivalent of commercial bearings to precision ones. What this thread has mostly been about is the history of ball bearings and fishing reels. It is clear that many reel makers, as you and many other have pointed out, have utilized ball bearings in their reels as early as the 1880s and 1890s. Maybe it is just me, but that itself seems a worthy subject of inquiry in and of itself. My original interest in precision ball bearings in fishing reels remains my main focus.

Todd

P.S. A hyper technical discussion of various ball bearings can be found at http://www.bearings.machinedesign.com/

There is a very real distinction between a ball bearing and a precision ball bearing. One distinction, as defined by Fuji Seisakusho's web site (they make ball bearings), is that precision ball bearings are required to have a tolerance over a micron (1/1000mm). Commercial ball bearings (also called unground ball bearings) have a tolerance of 1/100mm to 1/10mm. This is of course current terminology. As I mentioned previously, it was not until the WWII era where precision ball bearings became possible, in particular precision micro ball bearings. The distinction is made well in the following passage from a bearing manufacturer site:

"Commercial unground ball bearings are available as radial, thrust, or combination types. Basically, these ball bearings are made of a machined or stamped inner race, a full complement of hardened steel balls, and an outer race of one, two, or more machined or stamped parts...Misalignment has little effect on commercial unground ball bearing assemblies because of their greater internal clearances. Excessive misalignment destroys any bearing, but far less production accuracy is required with unground ball bearings. As a result, the entire assembly can be much simpler in construction than a precision bearing. The major advantage of unground ball bearings over the higher precision ball bearings discussed earlier is price. Unground ball bearings are far less expensive than the higher precision types. On the other hand, life of unground ball bearings is less than precision bearings...Unground ball bearings also operate at higher noise than precision bearings."

Now, as for fishing reels, my original question was precise: What was the first reel to use precision ball bearings? I later refined it to ask when fishing reels first utilized micro precision ball bearings. Basically, Steve, what this is all getting at is when the fishing reel industry first required such hyper technical precision when constructing their models. If you look at the specs of many modern reels such as the Swift Center-Pin Trotting Reel, GALAXY 600 BR, Daiwa Gyro Spin, Epix ER40 and many other reels, they SPECIFICALLY indicate precision ball bearings, meaning that these bearings have enormously high tolerances even when compared to standard bearings. The benefits of a precision ball bearing are many, including longer life, more precise mechanics, and smoother and more silent operation. The benefits of commercial ball bearings are price and degree of clearance. It should not be a surprise that many of the high-end reels advertise precision ball bearings. What I am trying to ascertain, for my own personal edification if nothing else, is when this shift happened and who was the first to do it.

You ended your series of questions with the following comment: "So I'm guessing that at any given time, reels were equipped with bearings of varying quality/precision, not much of a surprise." No, maybe not a surprise, but the creation of greater precision in fishing reel design is still perhaps one of the most important developments in the last 50 years of fishing reel design history. Precision ball bearings appear to have played an important role in this. Is that not worthwhile discussing?

The discussion here of when reels first utilized ball bearings is a logical outgrowth of trying to figure out when they switched from the equivalent of commercial bearings to precision ones. What this thread has mostly been about is the history of ball bearings and fishing reels. It is clear that many reel makers, as you and many other have pointed out, have utilized ball bearings in their reels as early as the 1880s and 1890s. Maybe it is just me, but that itself seems a worthy subject of inquiry in and of itself. My original interest in precision ball bearings in fishing reels remains my main focus.

Todd

P.S. A hyper technical discussion of various ball bearings can be found at http://www.bearings.machinedesign.com/

Thanks, Todd. All news to me. So the term "precision," as applied to ball bearings, denotes a tolerance of a micron, or 0.64 micron, using the Pierce figure, or less. And, presumably, it has always meant just that.

Of course the subject is worth discussing. I couldn't figure out what the precise subject was. "Precision," like "old," has always been a relative term for me. If ball-bearing people (so to speak) have made it into a more precise term, that's fine. When nano-scale bearings become widely used, though, they'll need to find a better term than "precision." Some folks have already been sliding things around on buckyballs. For example: http://www.iop.org/EJ/abstract/0957-4484/15/5/036 and http://orcaonline.org/images/pixel.gif ... 5-0020.htm

Of course the subject is worth discussing. I couldn't figure out what the precise subject was. "Precision," like "old," has always been a relative term for me. If ball-bearing people (so to speak) have made it into a more precise term, that's fine. When nano-scale bearings become widely used, though, they'll need to find a better term than "precision." Some folks have already been sliding things around on buckyballs. For example: http://www.iop.org/EJ/abstract/0957-4484/15/5/036 and http://orcaonline.org/images/pixel.gif ... 5-0020.htm

-

cws/carl schultz

- Advanced Board Poster

- Posts: 166

- Joined: Mon Dec 29, 2003 12:02 am

harvey

in your case more like barnicles

- Ron Mc

- Star Board Poster

- Posts: 3403

- Joined: Thu Apr 29, 2004 7:49 am

- Location: downtown Bulverde, Texas

- Contact:

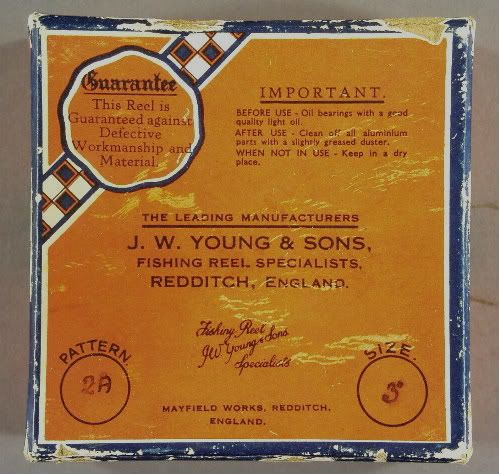

I suspect this is one of the earliest uses of a precision ball bearing in a UK reel.

Except for the sliding agate (well, and the lack of a clutch), this reel is essentially the same as a Ross Gunnison or J. Ryall, but made almost 50 years earlier.

The reel is marked Ogden Smith Exchequer. It uses the same casting as the Young style 2A reels (Zephyr/Fraser). The reel has a palming rim (caged spool).

But in addition to the optional check (click-pawl that can disengaged), there's a centrebrake mechanism - friction drag that tightens from the backplate.

The spool rides on a precision ball bearing. I suspect this reel was only made a few months before WWII, because this is only the second one I've seen, and I've only heard of one other. I'm hunting for a 1939 Ogden Smith catalog to try to learn some more.

Except for the sliding agate (well, and the lack of a clutch), this reel is essentially the same as a Ross Gunnison or J. Ryall, but made almost 50 years earlier.

The reel is marked Ogden Smith Exchequer. It uses the same casting as the Young style 2A reels (Zephyr/Fraser). The reel has a palming rim (caged spool).

But in addition to the optional check (click-pawl that can disengaged), there's a centrebrake mechanism - friction drag that tightens from the backplate.

The spool rides on a precision ball bearing. I suspect this reel was only made a few months before WWII, because this is only the second one I've seen, and I've only heard of one other. I'm hunting for a 1939 Ogden Smith catalog to try to learn some more.

Last edited by Ron Mc on Mon Feb 20, 2006 7:37 pm, edited 1 time in total.

Ball bearings

Yo Todd-Wow! What quick responses. F.M. Case used roller bearings (as a unit) in his patented drag as part of a multi-device patent. Check it out in the Enterprise Patent book. Pat. No. 1,554,786, p. 116. Will look for other Enterprise use of other type bearings. Bob from (NOT the University of) Tennessee

-

reels4me,member

Ball Bearings

What about the America#1 and #2 where do they fall chronologically ?

Me again Todd. I know this request concerns "precision" bearings, but got me awake about Enterprise bearing use in general. Check Pat. No. 1,832,421 (C.T.Pflueger and Walter L. Adams 11/17/31) for use of roller bearings in the "star" drag system. Also, it is possible that the "Automatic Thumber" device used on the Skilkast first in 1941 could have used bearings. Haven't taken one down far enough to tell. Don't know what the "Patent Pending" number was. Bob

I'm still not sure what this thread is about. Ball bearings have been in use since ancient times. A lot of patents were issued during the 19th century for ball bearings and for methods of making them. So let's use Todd's definition of a precision ball bearing as one "required to have a tolerance over a micron (1/1000mm)." (It's reasonable to assume that he means "under" a micron and that this tolerance considers only the sphericity of the balls themselves and not the fit within the race, temperature changes, lubrication requirements, etc.)

So the question arises: when was it first possible to produce balls for bearings with such tolerances? And who made them? And, again, what does "precision" mean? For example, one company claims that it has been making "precision" ball bearings "for over 75 years." (http://orcaonline.org/images/pixel.gif? ... _Balls.htm) That would take us back to about 1930, well before WWII. I certainly don't know the tolerances to which these bearings were made.

It's my understanding that the balls for these bearings are made by grinding them to within the desired tolerances. At least one German company was grinding balls (shudder) for bearings with ceramic plates by 1922. Meanwhile, Sven Wingquist had been making ball bearings in Sweden since 1907. Lea Rockwell's 1922 U.S. patent mentioned grinding spheres "in the usual way to a true sphere of the desired size." I have no idea to what tolerances these various products were made.

The U.S. patents issued before WWII included dozens and dozens of machines and methods for producing spherical metal balls and even more dozens of designs for single-race ball bearings. Presumably, bearing manufacture improved gradually over time, and, at any given time, high-quality bearings of varying degrees of "precision" were available to reel manufacturers. At what point was it suddenly possible to produce bearings of a given tolerance, and who was making them?

These days, specifications for ball bearings are set by the American Bearing Manufacturers Association (ABMA), and some of these are available free on the Internet (http://orcaonline.org/images/pixel.gif? ... ll_tol.htm). ABMA was formed in 1917, and I imagine that their standards have changed somewhat since then. It would be very helpful, for the purpose of this thread, to tie the question of whose reels used which ball bearings to a particular set of ABMA standards. At least then we would have a starting date and defined criteria by which to search for an answer.

It might not be a bad idea to ask ABMA itself what "precision" means now and what it meant in the past. They seem to love the word:

So the question arises: when was it first possible to produce balls for bearings with such tolerances? And who made them? And, again, what does "precision" mean? For example, one company claims that it has been making "precision" ball bearings "for over 75 years." (http://orcaonline.org/images/pixel.gif? ... _Balls.htm) That would take us back to about 1930, well before WWII. I certainly don't know the tolerances to which these bearings were made.

It's my understanding that the balls for these bearings are made by grinding them to within the desired tolerances. At least one German company was grinding balls (shudder) for bearings with ceramic plates by 1922. Meanwhile, Sven Wingquist had been making ball bearings in Sweden since 1907. Lea Rockwell's 1922 U.S. patent mentioned grinding spheres "in the usual way to a true sphere of the desired size." I have no idea to what tolerances these various products were made.

The U.S. patents issued before WWII included dozens and dozens of machines and methods for producing spherical metal balls and even more dozens of designs for single-race ball bearings. Presumably, bearing manufacture improved gradually over time, and, at any given time, high-quality bearings of varying degrees of "precision" were available to reel manufacturers. At what point was it suddenly possible to produce bearings of a given tolerance, and who was making them?

These days, specifications for ball bearings are set by the American Bearing Manufacturers Association (ABMA), and some of these are available free on the Internet (http://orcaonline.org/images/pixel.gif? ... ll_tol.htm). ABMA was formed in 1917, and I imagine that their standards have changed somewhat since then. It would be very helpful, for the purpose of this thread, to tie the question of whose reels used which ball bearings to a particular set of ABMA standards. At least then we would have a starting date and defined criteria by which to search for an answer.

It might not be a bad idea to ask ABMA itself what "precision" means now and what it meant in the past. They seem to love the word:

Bearings are highly engineered, precision-made components...enabling machinery to move at extremely high speeds and carry remarkable loads with ease and efficiency.

Bearings must be able to offer high precision, reliability and durability, as well as the ability to rotate at high speeds with minimal noise and vibration.

-

Richard Lodge

- Super Board Poster

- Posts: 1252

- Joined: Tue Sep 16, 2003 10:00 pm

- Location: Massachusetts

Git yer bearings....

Wow! This is a tremendous amount of information about fishing reels and maufacturing processes here. I sense a GREAT Reel News article in here, Dr. Larson!

-

guest

stock bearing

Just wondering when Ogden started using Hoffman bearings with their catalog or part number stamped to the bearing? Never have seen one like that before.

Commercial break

Just wanted to interrupt this thread to share the spam that arrived just after I posted the blather above. Maybe "RC Industry" means reel collecting. Kudos to these folks for gaining ISO9002!

And now, back to our thread...RE: PROMOTE RC INDUSTRY FOR BALL BEARINGS

Dear Merrs,

Glad to find your company on the internet, and knowed your company is specialized in R/C Industry which is of interest for us. Because we, a manufacturer in China, is majoring in ball bearings and one-way clutch bearings and balls etc, which are very matched with RC hobby. So, we take the liberty of introducing us to you directly.

We have 18 years of experience, and could design according to the customer's specification. We have gained ISO9002, and rigorous testing system. Competitive prices, excellent quality and punctual delivery is guaranteed. We are committed to providing a first class service too.

If you are interested in our products, please contact us now promptly via email or fax. We will make an effort to satisfy with you. Please also ask to obtain our list of price of our products. If they are not of interest to you, please do good enough to forward the message to your friends or a firm who is really interested in.

We are looking forward to your reply promptly.

Best regards,

Mr.Tony

Sales Manager

Fuzhou Newpower Bearings Ltd.

No.20 Qinyuan in Fuzhou Univ,

523, Gongye Road, GuLuo District,

Fuzhou, Fujian, 350002, China

Tel./Fax.: +86(0)591-8319-8892

http://www.npbearings.com

Email:tony[at]npbearings.com

- Ron Mc

- Star Board Poster

- Posts: 3403

- Joined: Thu Apr 29, 2004 7:49 am

- Location: downtown Bulverde, Texas

- Contact:

Re: stock bearing

(I'm sure we're talking about Hoffmann stock numbers, rather than Ogden Smith part number.)guest wrote:Just wondering when Ogden started using Hoffman bearings with their catalog or part number stamped to the bearing? Never have seen one like that before.

As I said, I've seen 2 of these reels, and heard of a third.

The Exchequer is the same casting as the reel below, but finished out with the bearing and centrebrake. This is how Ogden Smith specified the reel from Young.

This was the Exchequer, always the top of the line in OS catalogs. In the 20's, the Exchequer was a Dingley perfect, and through most of the 30s, it was a Young perfect. My best guess is that this reel was made for a few months before WWII. If you think about it, the model had ball bearings from day 1, so when they decided to convert to the caged spool reel (making this an upgrade of the Zephyr), they decided to add a ball bearing and centrebrake.

I'm trying to find catalog information to support this. Any idea what they were selling just after the war? I would be surprised if the lead finish was still being used after the war.

This Exchequer (above) came from the collection of Jamie Maxtone Graham. Unfortunately, no specific information came along with it.

Here's the Young 2A casting, finished for R&W Kerr, Ltd., Montreal.

guess it didn't show up as well in my photo as I thought, but the mark on the left says "Manufactured by JW Young & Sons Redditch"