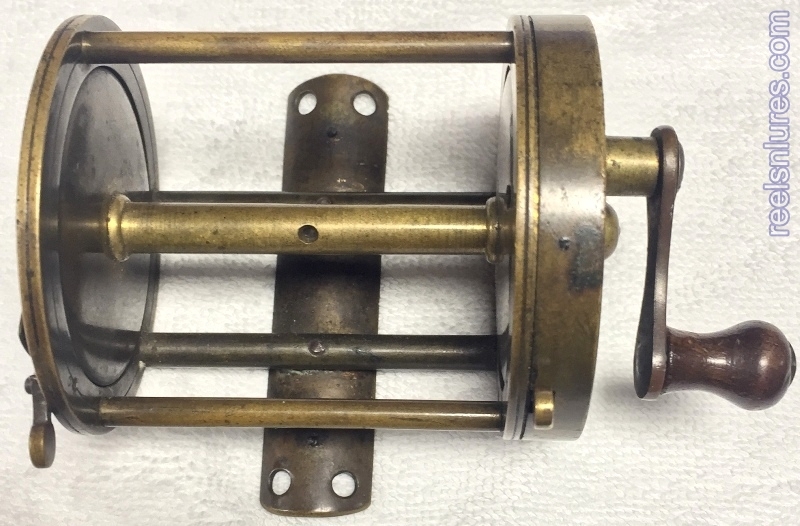

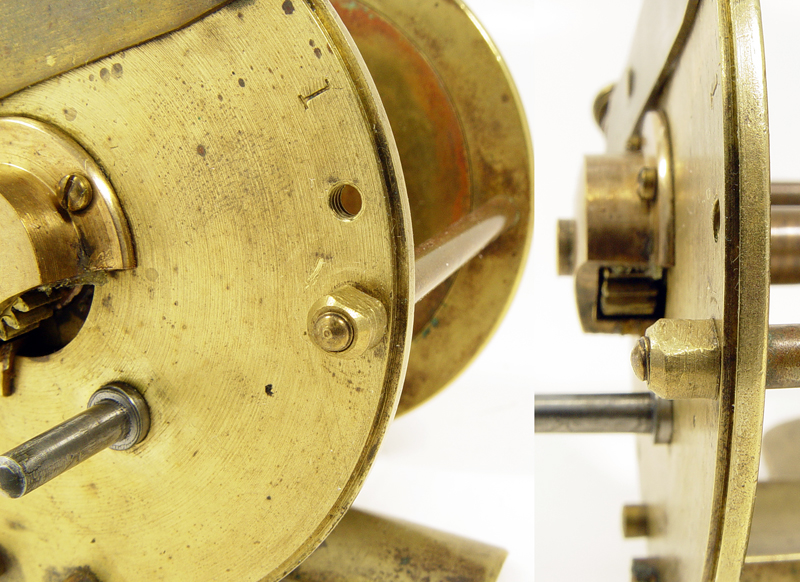

Some of us collectors focus on reels made as far in the past as possible. One indication of great age is the inclusion of two-piece metal sideplates. In most "classic" metal reels, the sideplates have internal recesses to accommodate the flanges of the spool. The recesses are usually formed by milling of the discs used for the plates. The milling requires care to ensure that the recesses are neither too deep nor too shallow. The procedure also wastes a lot of metal.

Some very old reels were made with two pieces of metal, a disc and a ring of similar diameter, that were soldered together to form a recessed plate. Several examples are shown below. Some makers may have used this method simply because their milling talents were lacking or because they didn't want to waste the expensive metal lost to milling. Nevertheless, I believe that the use of two-piece plates is an indication of great age.

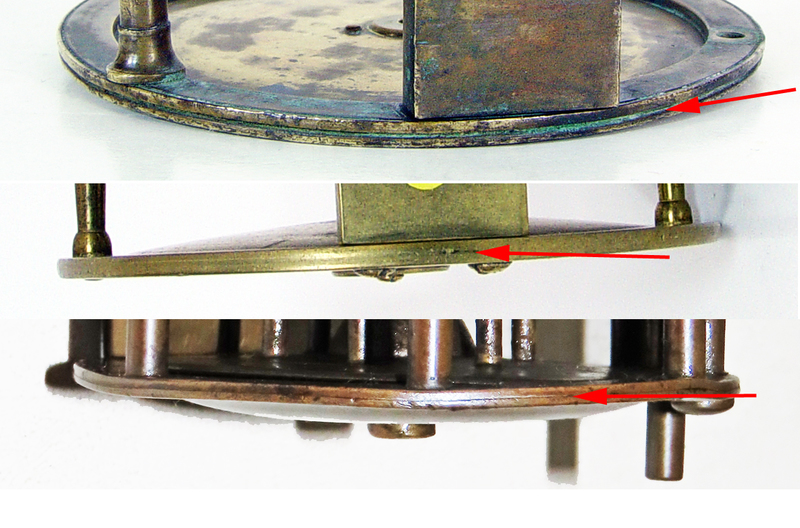

If anyone can post some info on when this practice may have been superseded by milling, I would appreciate it. In the meantime, here are some examples of two-piece plates. Seams like those indicated by the arrows are often hard to see, especially on reels whose plate edges have been carefully smoothed and polished by the maker or later owner.

Two-piece construction of various reel components often is a sign of age. Two-piece reel feet were discussed recently in this forum. Some of the earliest J.F. & B.F. Meek reels had headcaps made of rims fastened to discs. These two-piece sideplates are additional examples of parts that were difficult or cheaper to make before the requisite developments in machinery or techniques enabled one-piece construction.