I was wandering through a flea market a few weeks back and I tripped across a bunch of old billiard balls for 2 bucks each. Some were pretty old and I thought I might get lucky and find that some were ivory, so I snatched up several cue balls and dragged them home. Well, needless to say, there were no ivory balls and a couple of them were plastic that weren't much good. However, several were, from the smell when cut, made from a phenolic resin and they proved to be pretty good material for making handle grasps.

First order of business was to try and lop off some useful pieces from a round cue ball. You have to be really careful doing this on a band saw..if you try to take to much at one time, it will grab and get ugly. So, the trick is to trim off just enough to give a flat surface to sit on the table while you make the next cut at 90 degrees. Once you get it reasonably stable on the saw table, you can then make some rectangles for the lathe.

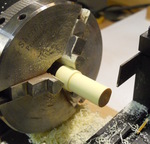

then the blank is turned down to the size of the grasp you need. Here, I'm putting a grasp on a Meek handle and using a Meek bluegrass handle as a model:

Once the center hole is cut, you can use the bit or a rod to keep the orientation the same as you flip the blank to work the whole thing. Given the losses one takes in making a round ball square, you need to try and hold onto as much blank as you can.

The final grasp needs some fine tuning to make sure it turns free on the shaft and fits snugly, but not too tight. A final polish brings it pretty much to the shine one sees on old grasps. As you can see from the outside of the cue ball, time will result in yellowing and toning down the white shade of the fresh-cut material.